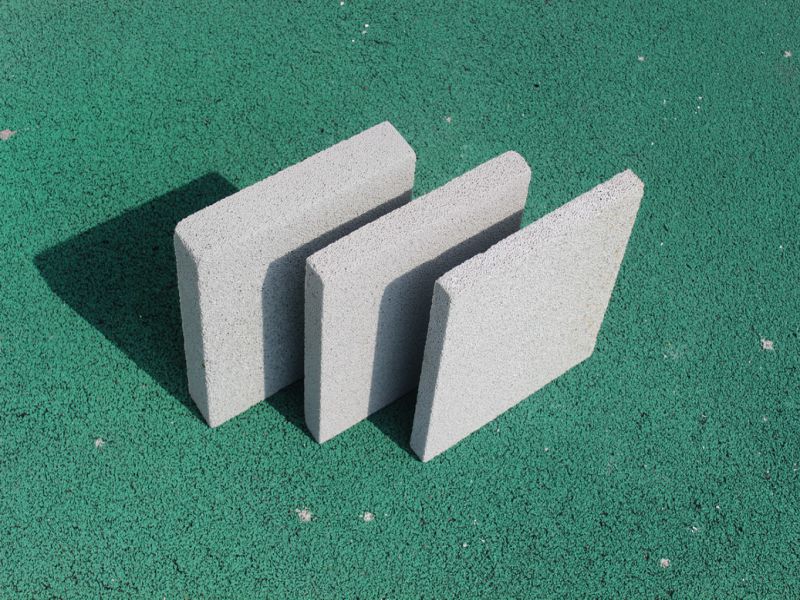

Ceramic fiber board was made by desiccation, machining and refined through vacuum forming or dry process. It’s an ideal energy saving material for kiln, pipe and other insulation equipment.

The advantages of

ceramic fiber board:

1. High compressive strength and long service life.

2. Low heat capacity and conductivity.

3. Non-brittle materials, good tenacity.

4. Precise size, good flatness.

5. Easy to cut and mount, convenient construction.

6. Good performance at anti erosion.

7. Continuous production, uniform fiber distribution and stable performance

Characteristic of

ceramic fiber:

Beside the fine properties of bulk ceramic fiber cotton, ceramic fiber board has hard texture, excellent toughness and strength and good performance at weather-proof. It won’t expand when heated. Besides, it has light weight so that it can be constructed convenient and arbitrary shear bending.

The application of ceramic fiber board:

1. The backing insulation for kiln of cement and other building materials.

2. The backing insulation for kiln of petrochemical, metallurgy, ceramics, glass industry.

3. The backing insulation for kiln of heat treatment.

4. The backing insulation for non-ferrous metals industries.

5. The backing insulation for high-temperature reaction and heating equipment.